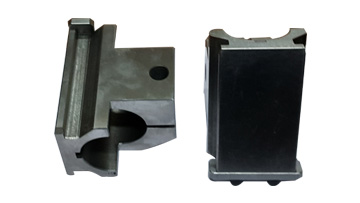

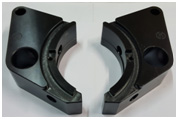

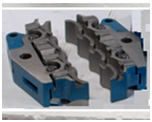

MOULD HOLDERS INSERTS

MOULD HOLDERS INSERTS Features & Benefits

- Many years experience has led company expertise in the manufacturing of Mould holder Inserts including many special purpose, which enable moulds designed for one type of I.S. machine to be used on a machine of different centers

- Made from ASTM graded ductile Iron casting and doing Gas Nitriding treatments to achieve longer life and stability of dimensional accuracy. Some of Hardened and Ground Plate type Inserts are made from AISI graded special Tool steel with RC 60 min.

- We maintain the perpendicularity of inserts within 25 micron with the reference of Insert pin bore.

- We can also supply with special treatments against Customer requirements to enhance much Longer Life along with Dimensional Stability through the process likewise :

A) Castings are Prior to machining quench hardened & temper to RC 35-40

B) Flame harden to RC 55 min. of Insert top seat.

Single Gob

Double Gob

Triple Gob

Quad Gob

| TYPE OF I.S. MACHINE |

MACHINE CENTER | ||||||||

| 2-1/8’’ | 3” | 3-5/16” | 4-1/4” | 5” | 5-1/2” | 6-1/4” | 76 mm | 85 mm | |

| S.G. | ■ | ■ | ■ | ||||||

| D.G. | ■ | ■ | ■ | ■ | |||||

| T.G. | ■ | ■ | ■ | ■ | ■ | ■ | |||

| Q.G. | ■ | ■ | ■ | ||||||

- A wide range of S.G., D.G., T.G. & Q.G Inserts for Blank and Blow Mould holders with all types of Upper, Lower, center mounted in Std. and offset types & plate types are available.

- Due to our vast experience, we can design & develop any type of Mould holders as per customer specification for any type of I.S. machines

- All assemblies parts are Interchangeable with original equipment & available as ex-stock