INSPECTION FIXTURES

INSPECTION FIXTURES

Features & Benefits

- Eliminate defects, improve and maintain your productivity by ensuring Mould & Neck Ring equipment is checked at regular intervals. Vary cost effective

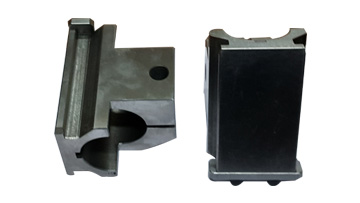

Mould Holder and Inserts Inspection Fixtures

- Early identification of Mould Holders & Inserts problems.

- Eliminate defects such as heavy seems or cross joints.

- Check inserts wear, bore diameter, misalignment & Mould arm height etc.

Neck Ring Arm Checking Fixtures

- Check for bore wear, the groove width distortion, foot flatness & centre error.

- Simple to use & very cost effective

Baffle Arm, Blow Head Arm and Funnel Arm inspection fixtures to check main co-ordinates holes position and alignment for trouble free performance on the I.S. Machine.

Plunger alignment fixtures.

- We can design and develop any type of inspection fixtures as per customer specification for any type of I.S. Machine.